Up to 24 cash back Detailed calculation than displays many calculated variables such as. Condenser Design Calculation Pdf To Excel.

Excel Calculations Double Pipe Heat Exchanger

MJCronin Mechanical 2 Jul 19 2338.

. Heat exchanger design handbook Juan Guillermo. With the heat load you calculate the required heat transfer area for the condenser. Air Cooled Condenser Design Spreadsheet - Download as Excel Spreadsheet xls PDF File pdf.

This is shown schematically in Figure 1It is important that the spray nozzles and vessel are designed to produce a fine spray of liquid to give a large interfacial area for heat transfer and a long enough residence time of liquid droplets in the vessel. June 30 2018 September 6 2019 hiadmin Heat Exchanger 4 Comments on Air Cooled Condenser. The thermal design of the typical steam plant is done by analysis developed specifically for power plant design.

Condenser Design Calculation Pdf To Excel 7710 4225votes. Design of condenser 1. Wet steam temperature is 37 C and enters the condenser with 095 quality dryness fraction is 095.

Condenser sizing How to design a shell-tube condenser. Data Sources for Default Values Used in Calculations. All these calculations should already have.

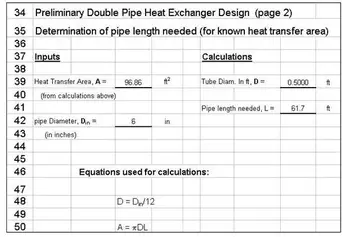

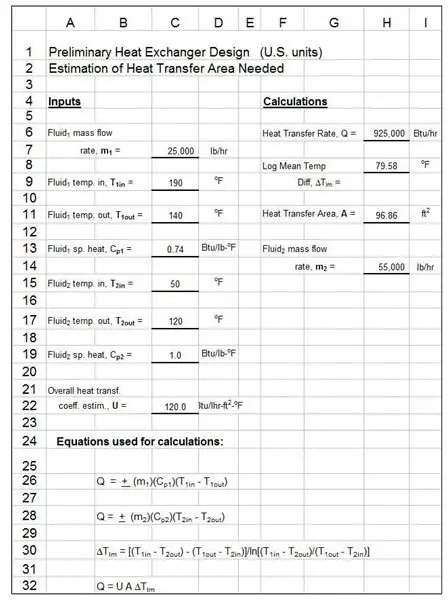

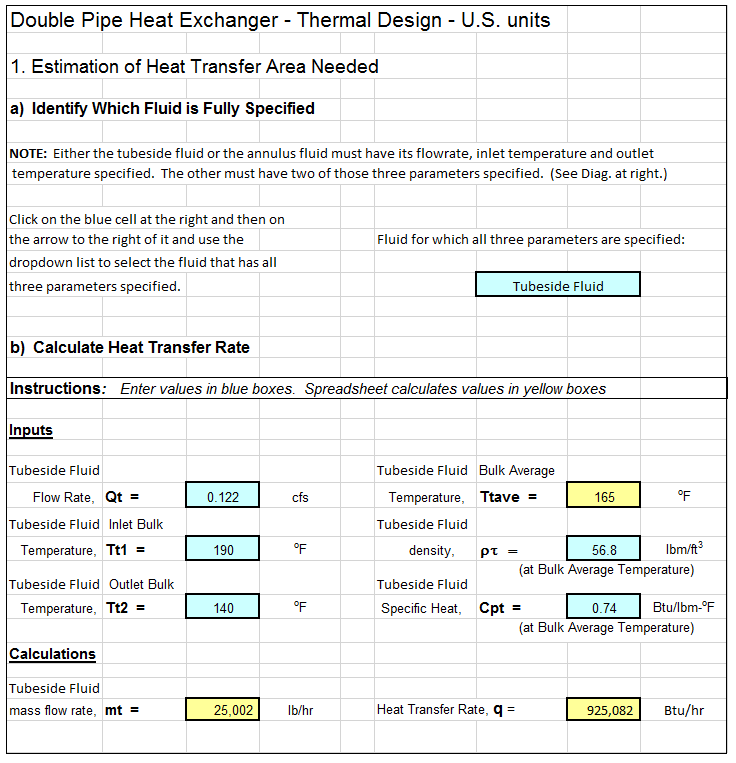

After values are entered for those parameters the Excel formulas in the spreadsheet will calculate the heat transfer rate the log mean temperature difference the required heat transfer area and the needed mass flow rate for the second fluid. Divided by the inlet pressure p v c von 1000 Pa we obtain a pumping speed S 1 von 0397 m 3 s -1 or 1429 m 3 h -1. Data sheet in Microsoft Excel for.

Calculate the overall heat transfer coefficient. Calculate the required heat transfer area based on values needed. - Inlet pressure 120 bar inlet temperature 7 C.

The interface is in excel format which makes it easy for anyone to quickly learn. Duty Area Number of tubes ShellTube velocities flooding velocity and operating velocity for reflux condenser Reynolds numbers Condensation heat transfer coefficient Condensation flow regime Number of Baffles and Baffle spacing Scale resistance dirt factor Overall heat. Select the Cost Estimate tab to view the estimated installation and operation costs for the condenser.

Detailed calculation than displays. Condenser Design - Excell Spreadsheet. Steps for design of heat exchanger Calculate the effectiveness.

Surface condenser design calculation. Data Element Default Value Sources for Default Value Recommended data sources for site-specific information. The water used for cooling has the following data.

We are United Heat Exchanger providing solution for Air condensation system for all types of Thermal Power plantsIn systems involving heat transfer a. References process heat transfer principles and applications by ROBERT W SERTH Heat and mass transfer cengel and ghajar. Download the Excel spreadsheet templates in this article to make preliminary heat exchanger design calculations.

PROCESS DESIGN OF SHELL AND TUBE HEAT EXCHANGER CONDENSER AND REBOILERS. Air Cooled Condenser. Up to 24 cash back Selection of software according to Condenser design calculation excel topic.

Calculate the heat transfer surface area. Ive attach the excell sheet in designing the condenserplease comment on thisso that i can improvethanks. A condenser aims at sufficiently cooling down a vapor thanks to a.

- posted in Student. From Thermal design calculations of Shell. Calculate the length of the tube or heat exchanger.

These templates use SI. Condenser Calculation Using Thermo Utilities MS Excel Add-ins A surface condenser is required to deal with 15 000 kgh wet steam. Shell and tube condenser design.

Get the design data The. This software application is intended for use by professional and academics in the engineering industry. Free Excel condenser.

You need to calculate the heat load on the condenser select the cooling medium for the condenser and calculate the flow rate of the cooling medium. DESIGN CALCULATIONS FOR CONDENSER Inlet temperature of the process stream T1 45 o C Outlet temperature of the process stream T2 45 o C Inlet temperature of the water t1 25 0 C Outlet temperature of the water t2 40 o C Mass flow rate of the process stream m 8060 Kghr Enthalpy of Vapors of Process Stream 1940 KJKg. The first step is to calculate the gas flow from the chamber.

Calculation of heat transfer co. The coolant is sprayed using nozzles into a vessel to which the vapor is supplied. Realize that the design of your steam surface condenser must fit into the thermal design of your plant.

Download Condenser Design for Windows to perform thermal design calculations for shell and tube condensers. So for the case of condenser duty Q L M x Lam U x A x LMTD So our Required Heat Transfer Area A M x Lam U x LMTD U value can be considered in between 300 - 450 KCalSqm hrC this value is not a thumb value but generated from average of different trials taken while designing the condensers. This software incorporates many of the thermal.

Condenser definition What is a condenser. Air cooled condenser design calculation excel. Support SI UnitsEnglish US Units of measurement Units converter containing 23 measurements and 200 units.

21 STEP 1. Q p v c S 1. Column C has cells for entry of several parameter values.

FOR EDUCATIONAL PURPOSE ONLY DO NOT USE THIS METHOD FOR DETAIL DESIGN ALWAYS CONSULT A REPUTABLE SUPPLIER FOR DETAIL DESIGN Condenser sizing calculation tool Input Results Orientation Heat exchange area m2 Condenser Horizontal Number of tubes Tube length m Tout Tin Cooling fluid Number of passes Water Overall heat exchange. You are able to add in extra rows to your pressure drop calculation similar to how you would with excel. Calculation of condenser heat load is.

Condenser Design has had 1 update within the past 6 months. Up to 24 cash back The effectiveness of a condenser can be calculated as 1 - eNTU NTU UACmin Cmin mCpmin. Condenser design Igwe Johnson.

For sizing a heat exchanger several thermal phenomena should. This software can design horizontal shell side condensers horizontal tube side condensers vertical shell side condensers vertical tube side condensers and reflux condensers. They will also calculate the number of tubes needed for a shell and tube heat exchanger and to calculate the pipe length needed for a.

Calculate the capacity rate ratio. We obtain a gas throughput for air of 12 Pa m 3 s -1 and for water vapor of 385 Pa m 3 s -1 together 397 Pa m 3 s -1. Shell Tube Condenser Design software is made to perform thermal analysis and.

Tab to see the calculated design parameters for your condenser. The HVAC condenser water pump calculator is designed to be comprehensive to apply to nearly all condenser water designs but also simple and easy to use.

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

Excel Calculations Tema Type E Heat Exchanger Design

Condenser Design Calculation Method

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

Heat Exchanger Thermal Design Calculations Spreadsheetlow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheets

Excel Calculations Double Pipe Heat Exchanger

Condenser Calculation Using Thermo Utilities V2 0 Ms Excel Add Ins

0 comments

Post a Comment